Nuts are one of the most essential components in the world of fasteners. They play a crucial role in holding various components together and ensuring that they do not come apart due to vibration, shock or other forces.

Nuts are a type of fastener that is used in conjunction with bolts or screws to secure two or more components together. In this buyer's guide, we will take a closer look at the different types of nuts available, the factors to consider when purchasing nuts, and other essential information.

Types of Nuts

There are various types of nuts available, each with its unique design, shape, and application. Each type of nut has its unique design, advantages, and disadvantages. Choosing the right type of nut for your application depends on various factors, such as load capacity, environment, and installation requirements.

Understanding the different types of nuts available can help you make an informed decision when purchasing nuts. Here are some of the most common types of nuts.

Cap Nuts

Cap nuts are dome-shaped nuts that are designed to cover the exposed end of a bolt or screw. They are mainly used for aesthetic purposes and to protect the threads of the bolt or screw from damage.

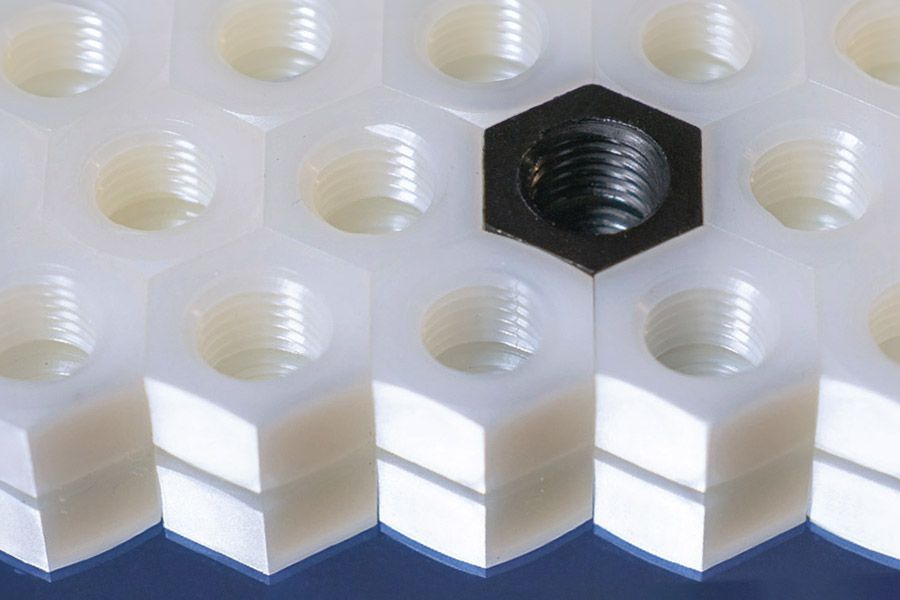

Hex Nuts

Hex nuts are one of the most common types of nuts used in various applications. They are designed with six sides and are tightened using a wrench. Hex nuts are available in various sizes and materials, making them suitable for various applications.

Captive Nuts

Captive nuts are a type of nut that is permanently attached to a component. They are commonly used in situations where it is challenging to access the backside of a component, making it impossible to use traditional nuts.

Wing Nuts

Wing nuts are designed with two large wings that make them easy to tighten and loosen by hand. They are commonly used in situations where a component needs to be frequently removed and reinstalled, such as in plumbing or electrical work.

Wing nuts are also useful when a tool is not available for tightening or loosening nuts.

Lock Nuts

Lock nuts are designed to prevent the nut from coming loose due to vibration or other forces. They achieve this by using a locking mechanism that ensures the nut remains in place.

Different Types of Materials

Nuts are available in various materials, each with its unique properties and advantages. The material you choose depends on various factors such as environment, application, and load capacity.

Steel

Steel is the most common material used for nuts. It is durable, strong, and can handle high loads. Steel nuts are available in various finishes, such as zinc-coated, black oxide, or chrome-plated.

Stainless Steel

Stainless steel nuts are ideal for applications where corrosion resistance is essential. They are commonly used in outdoor applications or in corrosive environments.

Brass

Brass nuts are commonly used in applications where aesthetics are essential. They are commonly used in furniture and other decorative applications.

Nylon

Nylon nuts are lightweight and have excellent chemical resistance. They are commonly used in electrical applications due to their insulating properties.

Aluminium

Aluminium nuts are lightweight and have excellent corrosion resistance. They are commonly used in applications where weight is a concern.

Titanium

Titanium nuts are strong and lightweight, making them ideal for high-performance applications. they are commonly used in aerospace and military applications.

Factors to consider when purchasing nuts

When purchasing nuts, there are several factors to consider to ensure that you choose the right nut for your application.

Size: The height and width of the nut should match the size of the bolt that it will be used with. Using a nut that is too small or too large can result in damage to the bolt or the nut, which can cause the fastener to fail.

Material: The material of the nut should match the material of the bolt and the application. For example, if the bolt is made of stainless steel, a stainless-steel nut should be used to prevent corrosion or galvanic corrosion.

Thread Pitch: The thread pitch of the nut should match the thread pitch of the bolt. Using a nut with the wrong thread pitch can cause cross-threading, which can damage the threads on the bolt and the nut.

Torque: The torque specifications for the nut should be followed to ensure that the fastener is properly tightened. Under-tightening or over-tightening can result in failure of the fastener.

Environment: The environment in which the nut will be used should be considered when choosing the material of the nut. For example, if the nut will be exposed to high temperatures, a high-temperature material should be used.

Load Capacity: The load capacity of the nut should match the load capacity of the bolt and the application. Using a nut with a lower load capacity than the bolt can result in failure of the fastener.

Cost: The cost of the nut should be considered, but it should not be the sole factor in choosing the nut. Choosing a cheaper nut that is not suitable for the application can result in failure of the fastener.

Conclusion

Choosing the right type of nut is essential to ensure the reliability and safety of your application. By understanding the different types of nuts and the factors to consider when purchasing nuts, you can make an informed decision and choose the right nut for your application.

FAQs:

What is the difference between a cap nut and a hex nut?

A cap nut is a type of nut that covers the end of a bolt, while a hex nut has six sides and is used to secure a bolt.

What is a captive nut?

A captive nut is a type of nut that is permanently attached to a piece of equipment, so that it cannot be lost.

Can a wing nut be used in high-vibration applications?

No, wing nuts are not suitable for high-vibration applications as they can come loose easily.

Can I use a lock nut in place of a regular nut?

Yes, you can use a lock nut in place of a regular nut. However, lock nuts are typically used in applications where there is a risk of the nut coming loose due to vibration or movement, whereas regular nuts are used in standard applications where there is less risk of the nut coming loose.

If you are unsure whether you need a lock nut or a regular nut, consult with a NPA professional or refer to the manufacturer's recommendations.

Are lock nuts necessary for all applications?

Lock nuts are not necessary for all applications, but they are recommended for applications where vibration or movement may cause the nut to come loose. If you are unsure whether you need a lock nut, consult with a professional or refer to the manufacturer's recommendations.

Can I reuse nuts?

It is generally not recommended to reuse nuts, as they may become damaged or weakened over time. Always use new nuts for maximum safety and security.

If you’d like some advice on nuts and bolts, phone NPA today on (08) 8268 2733 or browse our online store here to see our extensive range.