Types of Threaded Rods

There are different types of threaded rods, including nylon and stainless steel:

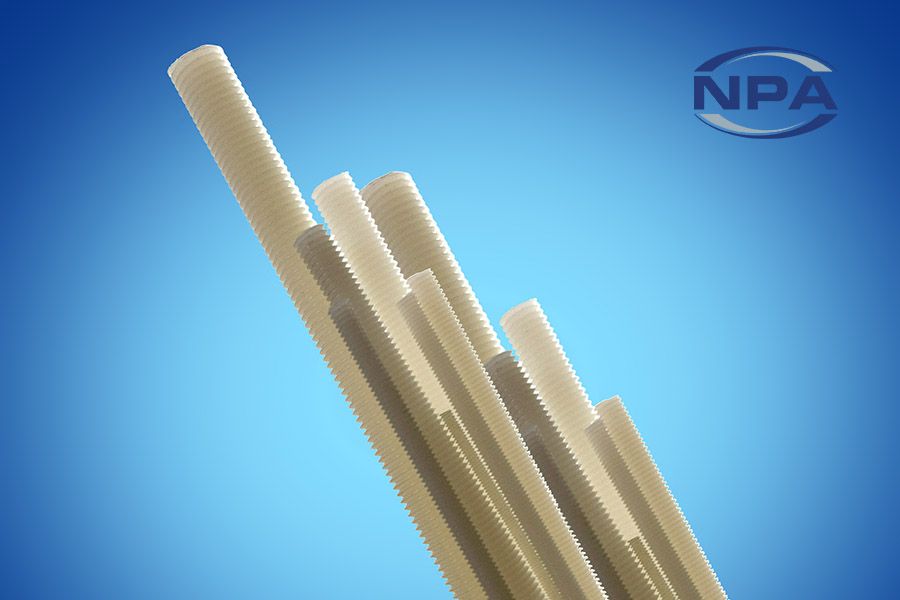

Nylon Threaded Rods

Nylon threaded rods are made of a durable and lightweight polymer that offers excellent chemical and corrosion resistance. They are ideal for use in applications that require electrical insulation and low friction, such as in electrical installations, machinery, and automotive industries.

Stainless Steel Threaded Rods

Stainless steel threaded rods are a popular choice for applications that require excellent corrosion resistance and strength. They are ideal for use in harsh environments, including marine and outdoor applications. Stainless steel threaded rods come in different grades, including 304 and 316, each with varying levels of corrosion resistance.

Nylon Versus Stainless Steel Threaded Rods

When choosing between nylon and stainless steel threaded rods, there are a few factors to consider. Here are some reasons why you might choose one over the other:

Nylon Threaded Rods:

- Lightweight: Nylon threaded rods are much lighter than stainless steel threaded rods, making them suitable for applications where weight is a concern.

- Non-Conductive: Nylon is a non-conductive material, making it suitable for applications where electrical conductivity is a concern.

- Chemical Resistance: Nylon is resistant to many chemicals, making it suitable for applications where exposure to chemicals is a concern.

- Cost-Effective: Nylon threaded rods are generally less expensive than stainless steel threaded rods.

Stainless Steel Threaded Rods:

- Strength: Stainless steel threaded rods are much stronger than nylon threaded rods, making them suitable for applications that require high load capacities.

- Corrosion Resistance: Stainless steel threaded rods are highly resistant to corrosion, making them suitable for applications that are exposed to harsh environments or chemicals.

- Temperature Resistance: Stainless steel threaded rods can withstand higher temperatures than nylon threaded rods, making them suitable for high-temperature applications.

The exact temperature range that stainless steel threaded rods can withstand will depend on the specific grade of stainless steel used. However, in general, stainless steel threaded rods can withstand temperatures ranging from -40°C to 650°C

Nylon threaded rods on the other hand generally have a recommended temperature range of -30°C to 50°C - Aesthetic Appeal: Stainless steel threaded rods have a polished finish that is aesthetically pleasing, making them suitable for applications where appearance is a concern.

Ultimately, the choice between nylon and stainless steel threaded rods will depend on the specific requirements of your application. If weight, non-conductivity, and chemical resistance are important, nylon threaded rods may be the better choice.

However, if strength, corrosion resistance, temperature resistance, and aesthetic appeal are important, stainless steel threaded rods may be the better choice.

Key Factors to Consider when Purchasing Threaded Rods

When choosing the right threaded rod for your needs, consider the following key factors:

Material Type: The material used to make the threaded rod is a crucial factor to consider. Different materials have varying levels of corrosion resistance, tensile strength, and temperature resistance.

As mentioned above, nylon and stainless steel are common materials used to make threaded rods, but there are other options like aluminium and brass.

Diameter and Length: The diameter and length of the threaded rod are also essential factors to consider. The diameter determines the strength of the rod, while the length determines how much thread engagement you need. Ensure that you choose a rod with the correct diameter and length for your application.

Thread Type: The thread type is another crucial factor to consider. There are different thread types, including coarse and fine threads, that suit different applications. Coarse threads are ideal for applications that require quick assembly, while fine threads are suitable for applications that require high tension.

Tensile Strength: Tensile strength is the maximum amount of force a threaded rod can withstand before breaking. It is an essential factor to consider when selecting a threaded rod. Ensure that the threaded rod you choose has the appropriate tensile strength for your application.

Corrosion Resistance: The level of corrosion resistance of the threaded rod is crucial, especially if you are using it in harsh environments. Stainless steel threaded rods are ideal for harsh environments, while nylon rods are ideal for applications that require electrical insulation.

Temperature Resistance: The threaded rod's temperature resistance is an essential factor to consider, especially if you are using it in high-temperature environments. Ensure that you choose a threaded rod with the appropriate temperature resistance for your application.

Compliance with Industry Standards: Ensure that the threaded rod you choose complies with industry standards. Compliance with industry standards ensures that the threaded rod meets specific requirements for quality and performance.

How to Choose the Right Threaded Rod

Choosing the right threaded rod can be a challenge, but following these steps can help:

- Identify your application's requirements: Determine the application's specific requirements, including the load capacity, environmental conditions, and other relevant factors.

- Determine the material type: Choose the material type that is appropriate for your application. Consider the material's strength, corrosion resistance, and temperature resistance.

- Choose the appropriate diameter and length: Determine the appropriate diameter and length of the threaded rod based on the application's requirements.

- Select the appropriate thread type: Select the appropriate thread type based on the application's requirements.

- Consider the tensile strength: Consider the threaded rod's tensile strength to ensure that it can withstand the application's load capacity.

- Ensure compliance with industry standards: Choose a threaded rod that complies with industry standards to ensure quality and performance.

Best Practices for Using Threaded Rods

Here are some best practices for using threaded rods:

- Ensure proper installation: Follow the manufacturer's instructions to ensure proper installation of the threaded rod.

- Use appropriate fasteners: Use appropriate fasteners, including nuts and washers, to ensure a secure connection.

- Tighten the fasteners properly: Tighten the fasteners to the recommended torque to ensure a secure connection.

- Inspect the threaded rod regularly: Regularly inspect the threaded rod to ensure that it is in good condition and functioning correctly.

- Replace worn or damaged threaded rods: Replace worn or damaged threaded rods to ensure the safety and reliability of your application.

Conclusion

Choosing the right threaded rod is essential for ensuring the safety and reliability of your application. Consider the material type, diameter, length, thread type, tensile strength, corrosion resistance, temperature resistance, and compliance with industry standards when selecting a threaded rod. Follow the manufacturer's instructions and best practices for using threaded rods to ensure a secure and reliable connection.

FAQs

- What is the maximum temperature a threaded rod can withstand?

The maximum temperature a threaded rod can withstand depends on the material used to make the rod. Stainless steel threaded rods can withstand temperatures higher than nylon threaded rods which generally have a maximum temperature of 50°C. - What is the difference between coarse and fine threads?

Coarse threads are suitable for applications that require quick assembly, while fine threads are suitable for applications that require high tension. - Can threaded rods be cut to size?

Yes, threaded rods can be cut to size using a hacksaw or a bolt cutter. - Are threaded rods sold in lengths?

Yes, they can be purchased in lengths, for example, 1m lengths.

- Can I use a threaded rod for structural applications?

Yes, threaded rods can be used for structural applications. However, ensure that the threaded rod meets the required strength and compliance standards.

If you’d like some advice on nylon threaded rods, phone NPA today on (08) 8268 2733 or browse our online store here to see our extensive range.